Introduction: Luogang brand permanent magnet variable frequency screw air compressor uses a permanent magnet variable frequency synchronous motor. Combined with intelligent frequency conversion technology, the permanent magnet variable frequency air compressor is more energy-saving than ordinary power frequency air compressors.

The servo permanent magnet variable frequency synchronous motor has a high rated working efficiency, which is 15-30% higher on average than a three-phase asynchronous motor with the same power and IE2 energy efficiency level.

Servo permanent magnet variable frequency synchronous motor. The motor stator adopts high magnetic permeability and low loss silicon steel sheets and special high-frequency windings. The rotor adopts high-performance neodymium iron boron magnets. The motor structure has small size, low inertia, high rigidity, high efficiency and low cost. Noise, fast response, smooth operation, precise control, strong overload capability and other advantages.

Features of servo permanent magnet variable frequency synchronous motor:

1. High power factor and high efficiency. The power factor of the motor is as high as above 0.95, and some are close to 1. It can save considerable electric energy in continuous fixed operating loads. The power saving effect is particularly significant in continuous periodic loads, saving about 30% of power than traditional motors. It can achieve the purpose of energy saving and emission reduction, and create benefits for enterprises.

2. Simple structure and reliable operation . Due to the inherent characteristics of permanent magnet materials, it no longer requires external energy to establish a strong permanent magnetic field in the space around it. This can simplify the motor structure, improve efficiency, save energy, and is a good energy-saving motor.

3. Unique design and durability. It generates very little heat and adopts a fully enclosed design, which perfectly solves the problem of iron-containing dust entering the motor and causing motor coil failure. At the same time, the heat resistance of the motor material is up to 180°C. Permanent magnet variable frequency screw air compressor

Product features:

1. More energy-saving than ordinary variable frequency screw air compressors.

2. Adopting the internationally advanced host machine and the best profile design, it has large exhaust volume, low noise and high stability.

3. Permanent magnet synchronous motor eliminates unloading loss, IP54 protection level, safer, more efficient and more energy-saving.

4. The main engine and permanent magnet motor adopt a direct-coupled split structure, which is highly reliable, safe and easier to maintain.

5. Adopt a special frequency converter for permanent magnet synchronous motor to achieve stepless speed regulation, constant pressure air supply and soft start, completely eliminating the loss of wasted work and intelligent air supply.

6. Fully intelligent control, dynamic display of system working conditions, real-time monitoring of important parameters, intelligent automatic power on and off, fully achieving continuous operation without supervision.

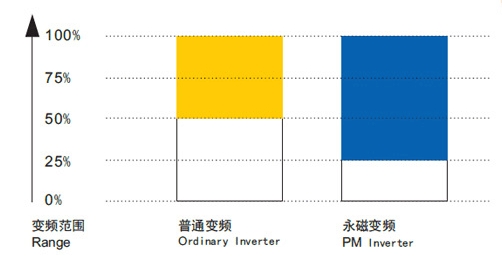

Comparison chart of frequency range between permanent magnet variable frequency air compressor and ordinary variable frequency air compressor

The permanent magnet frequency conversion range is 25% to 100%, and the ordinary frequency conversion range is from 50% to 100%.

Compared with fixed speed air compressor, energy saving is 20%~50%

Compared with ordinary variable frequency air compressors, it saves 10% to 20% energy.

★Intelligent LED liquid crystal display control system: Microcomputer intelligent monitoring system, fully automated Chinese and English display, touch buttons, easy to operate.

★Intelligent 360-degree all-round safety protection device saves you worry, effort and money

1. Excessive exhaust temperature protection 2. Exhaust pressure excessive protection 3. Power supply error protection (phase loss, reverse phase protection)

4. High current protection 5. Electrical failure protection 6. Motor overload protection 7. Fan motor failure protection 8. Oil pressure abnormality protection 9. Oil shortage protection

★Maintenance reminder function:

1. Air filter: digital pressure difference indication & warning reminder when usage time reaches set value

2. Oil filter: Digital pressure difference indication & warning reminder when usage time reaches set value

3. Oil and gas separator: digital pressure difference indication & warning reminder when the usage time reaches the set value

★Multi-machine chain remote monitoring system

In the office, you can monitor the operating status of the compressor from your computer at the same time, making it easier to manage the machine and saving energy.

Using the network, you can expand the monitoring scope and improve the maintenance operation time, total load time, exhaust pressure, exhaust temperature, operating current, fault details, etc. at a glance.